How To Help Businesses

With the evolution of time and the development of various information applications,our lives have become increasingly inseparable from the internet and various information services. In recent years, the architectures of Geographic Information Systems (GIS), Internet of Things (IoT), and Building Information Models (BIM) have gradually entered our lives. In response to the temporal, spatial, and diversified characteristics of data, leveraging the core technology of Three-dimensional Geographic Information Systems(3D GIS), we are constructing an information integration platform to provide comprehensive spatiotemporal alignment services.

In order to reduce industrial safety accidents in factories, 3D pipeline mapping has become one of the active management actions of the government and ente rprises.Through cross-platform integrated design, the future pipeline system is not just a single WEB-GIS system.it is also a mobile 3D-GIS system.The scope of opera tions is not limited.All pipeline information can be easily queried on the Internet, and appropriate spatial information can be provided.It can also provide real-time information when disasters occur, providing managers with the best Best support for decision-making.

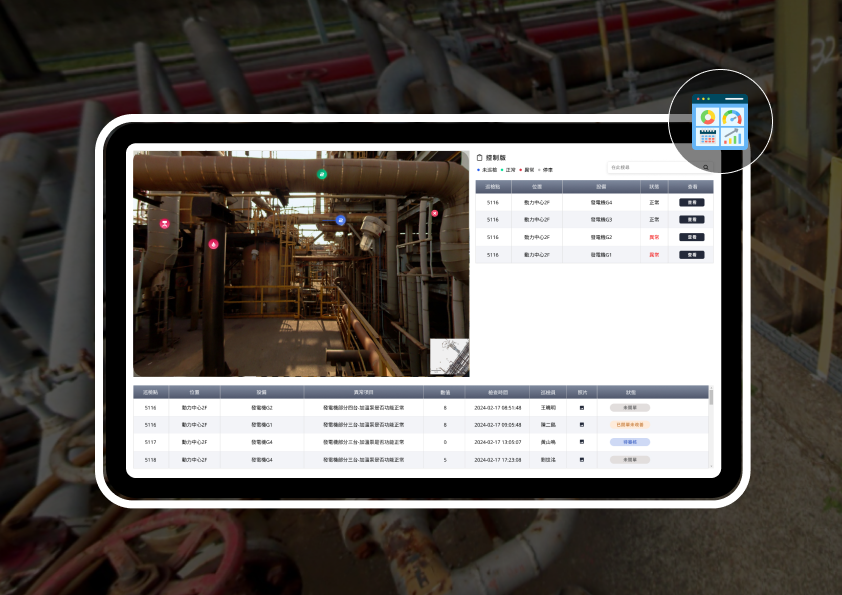

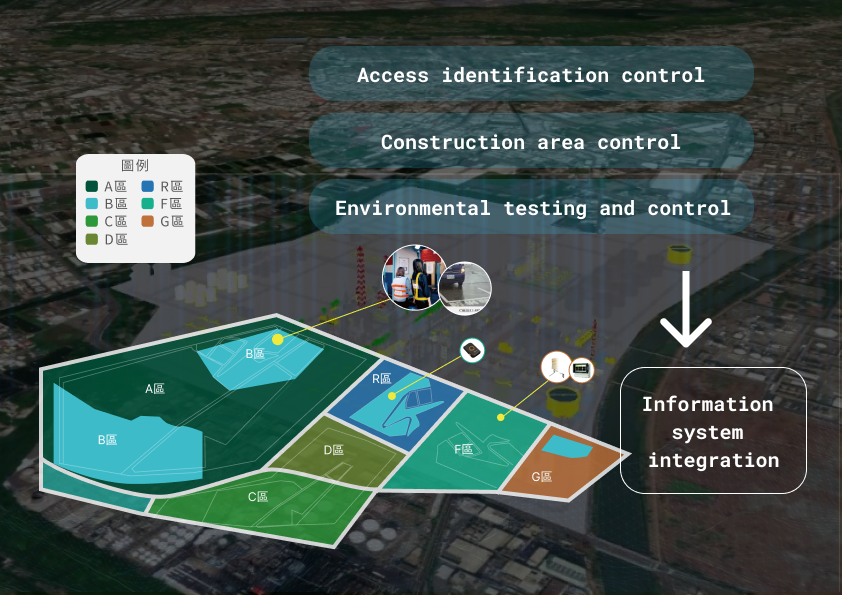

Hon-Tsai Technology undertakes the management system for contractor entry work permits and electronic inspection systems.It can integrate safety-related regulations for contractors in the plant, offering comprehensive functionali ty from basic data maintenance to handling abnormal entries and exits. Users can use handheld devices on-site to instantly view the operation and entry/exit status of contractor personnel, as well as the distribution of underground pipelines. It seamle ssly integrates with the existing inspection system, allowing on-site personnel to have real-time control over underground pipeline layout information and record daily business inspections. Through the 3D mapping platform, we establish a model of 'Precision 3D+Precision Positioning.' Project planning covers a 3D visualization mapping platform, on-site 3D scanning operations, and plant 3D model design. Depending on the scope of each project, we create databases and integrate real-time information such as plant control and safety monitoring. This enhances the adequacy and reliability of management data and real-time information.

The 3D mapping platform is a versatile geographic information integration and display analysis platform. It supports various base map switches, 2D layer interfaces (WMTS), 3D building import and display, point cloud data, underground pipelines, and object displays. It can import continuous data such as personnel access, PSM data, and location information. In the future, it can progressively develop different information models, extending applications to IoT, big data, and AI-related information technologies. This will lead to the creation of a comprehensive 'Smart Factory Management System Platform,' providing decision making assistance for management and becoming a new tool for promoting sustainable operations in safety management, project management , disaster prevention, and rescue management.

Design Concept

3D visualization

The area and equipment entering the factory are presented in a three-dimensional manner, and through the accurate three-dimensional model and management platform system, real-time functions such as measurement and cross-section dimensional measurement can be performed for each model.

Geolocation

You can have a clearer grasp of the precise location of various equipment in the entire region, as well as asset surveys.

Digital Transformation

This allows the establishment of a comprehensive database for each equipment or pipeline, facilitating a thorough digital transformation.

Integration with Applications

Capable of integrating maintenance and inspection information for a comprehensive maintenance management platform.

Establish virtual and real integration platform

Integrating system information from various devices, sensors, or SCADA, establishing a mixed reality data management platform to instantly grasp data and information across the entire area.

Management Records

Capable of establishing zone-based management and managing various equipment status indicators, setting equipment status KPIs to enable managers to consider management from a holistic perspective across the entire area.

Real-time Data Sharing

Built on the three-dimensional management platform, it establishes the capability to set up intelligent inspection functions freely and rapidly.In addition to real-time verification of inspection paths, it also allows for immediate reporting of inspection checklist functions.

Reporting and Analysis

Establishing the 'Advanced Smart Factory Information Strategic Management System' for the future plant, providing rapid access to factory information. Through strategic thinking and information collection across the entire area, it enables the analysis of management and production strategies. The integration of OT+IT+ST, even incorporating 5G (CT) networking strategies,enhances the adequacy and reliability of management data and real-time information.

System Overview

3D Mapping Platform

- Multidimensional perspective presentation

- Integration of CADc or ISO drawing files

- Built using Web and RWD architecture

- Provide management information dashboard

- Integration of Personnel, Vehicle, and Access Control Management

- System Integration of CCTV and GIS

- Capable of Establishing Plant Area Pipelines Facility Digital Database

On-Site 3D Scanning Operations

- LiDAR scan

- 3D Point Cloud

- Reverse Engineering Digitization

- Establishing Associative Relationships in Image File Data

- Data Synchronization for Shared Viewing

- Real-time Cross-Platform Information Synchronization

Industrial Site 3D Modeling

- Integration of Equipment and Facility Management

- Capability to Construct Architectural Models

- Capable of Constructing Pipeline and Steel Frame Models

- Integrating Work Permit System

- Capable of converting 2D CAD files into 3D architectural space models

Product Description

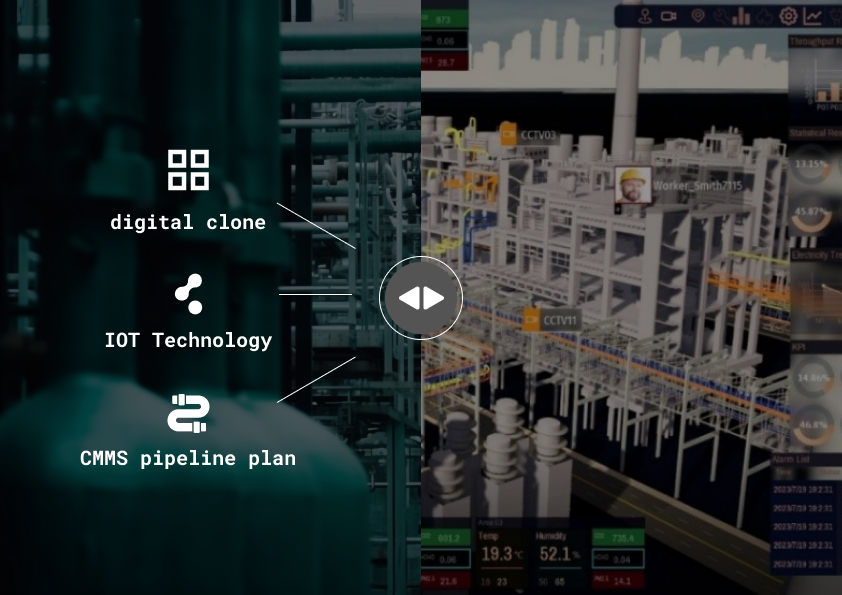

Integration of Virtual and Augmented Reality in Three-dimensional Space

- Integrating digital twins, Internet of Things (IoT) technology, and CMMS pipeline inspection plans, the on-site personnel distribution is presented through three-dimensional visualization, enabling managers to instantly grasp the current situation.

Capturing Data on People, Machines, Materials, Processes, and Environment

- Enhancing Management Efficiency:Three-dimensional visualization integrated with real-time information, enhancing managers' real-time control over field conditions.

- Improving Warning and Anomaly Handling Efficiency: Real-time updating of personnel location and job information within the factory area, automatic alerting in case of anomalies, and integration with online emergency response plan drills to reduce the risk of occupational incidents.

- Reducing Communication Time and Management Costs: Facilitating remote managers to quickly grasp on-site conditions, enabling swift inventory management, and tracking personnel, equipment, and asset records for real-time response to abnormal events.

Application Level

Toxic or Hazardous Area Information, Factory Equipment/Asset Management Information, Equipment Maintenance and Inspection Management Information, Contractor Vehicle Location Management Information, Work Permit Construction Site Management, etc.

Pipeline Monitoring and Diagnostic Module, Pipeline Optimization and Digital Twin Module, Pipeline Maintenance Management Module.

Intelligent Tracking Module, Abnormal Behavior Recognition Module, Linked Monitoring Module.

Environmental Monitoring Module, Safety Risk Assessment Module, Surrounding Community Impact Assessment Module.

Centralized Monitoring, Energy Management, Building Group Management, Facility Management, Real-time Imaging.

Anticipate risks, optimize task schedules, report equipment anomalies, emergency disaster reports, and inventory management records.