How To Help Businesses

Modern manufacturing plants are highly automated and mechanized, as production equipment have become an indispensable part, that failure of component, module or device for production (such as the heater, the pressure gauge, the throttle valve, etc.) can cause malfunction and delay the process. Frequent breakdown or short lifespan of equipment means spending time and money on repair for the business operator, not to mention the poor product quality or reduced production capacity that may even lead to heavy losses. Moreover, for quality, poorly maintained equipment will have less precision and will not be able to produce high-quality products. Or, the equipment that needs to stop for repair, will delay the business operator to meet the expected production quota to deliver the goods on time. All the above problems essentially boil down to the survival of business or even an entire industry. Simply put, regular upkeep of equipment will directly and indirectly affect production control, product quality, industrial safety, sales and other factors, so that routine maintenance is one of the issues that cannot be ignored by any businesses or industries.

Design Concept

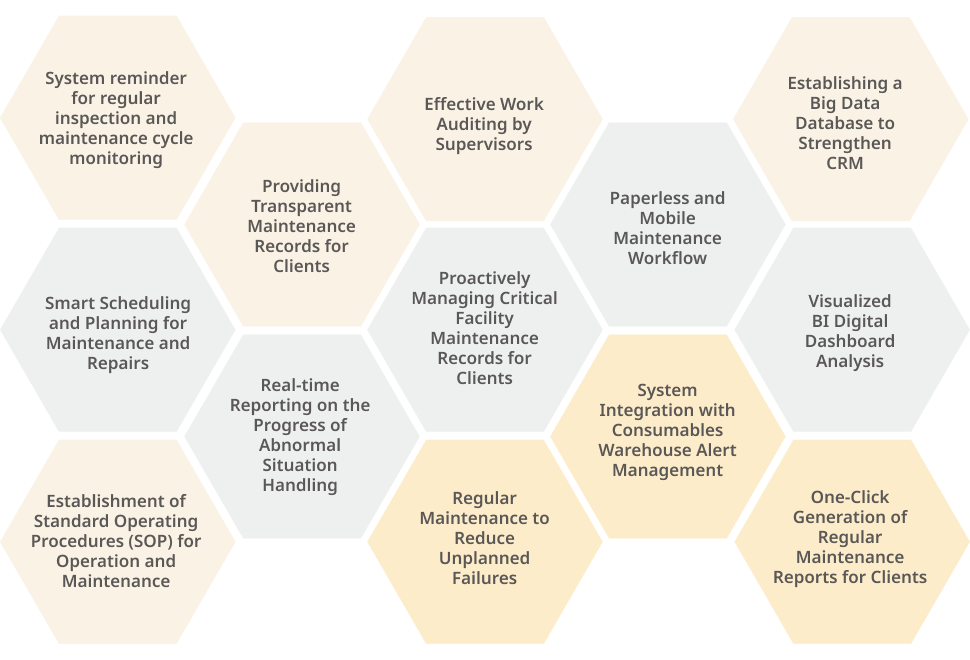

Integrate equipment inspection and maintenance operations

Computerization is the key cornerstone of our system for equipment inspection and maintenance, which will create a complete dataset of the facilities for a company.

Equipment maintenance and scheduling planning

The scheduling, inspection & maintenance and automatic inspection shall be included and upgraded as part of routine preventive maintenance plan.

Real-time access to facility status

These proactive measures will have the status, as well as the “life cycle” of equipment, on the watch to guarantee safe and effective operation of the facilities.

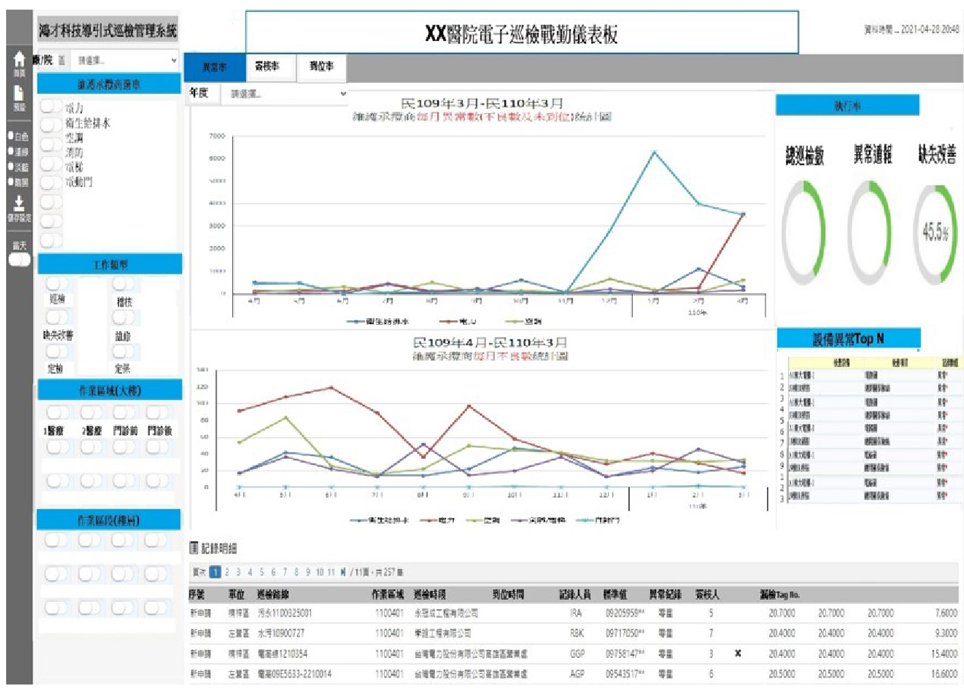

Establish risk management dashboard

A digital dashboard for risk control will ensure the full-time monitoring of the progress on exception handling.

System information E-output performance indicators

The incorporation of intelligent system for equipment inspection and maintenance will help to produce key indicators of facilities performance as part of the database for big data analysis.

Establish operation SOP for insurance operations

SOPs for routine maintenance and inspection are established to pass on certain skills and experiences to the novice personnel.

Comprehensive upgrade of web version and mobile version

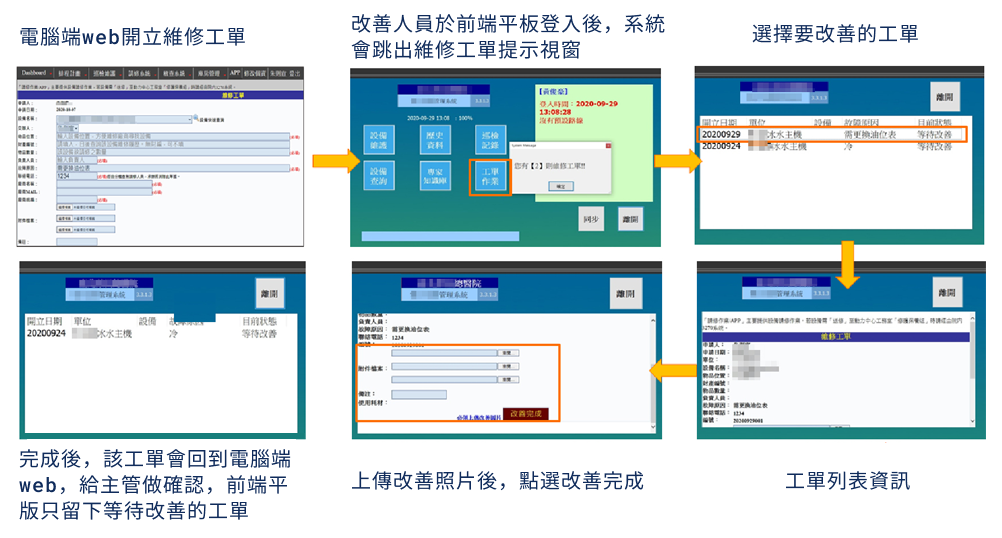

The input of request for work order of repair and maintenance will be upgraded to the Web and mobile access.

Asset/consumables/parts inventory incorporated into the system

The inventory of assets, consumables and parts are also incorporated into the system to achieve the goal of safekeeping.

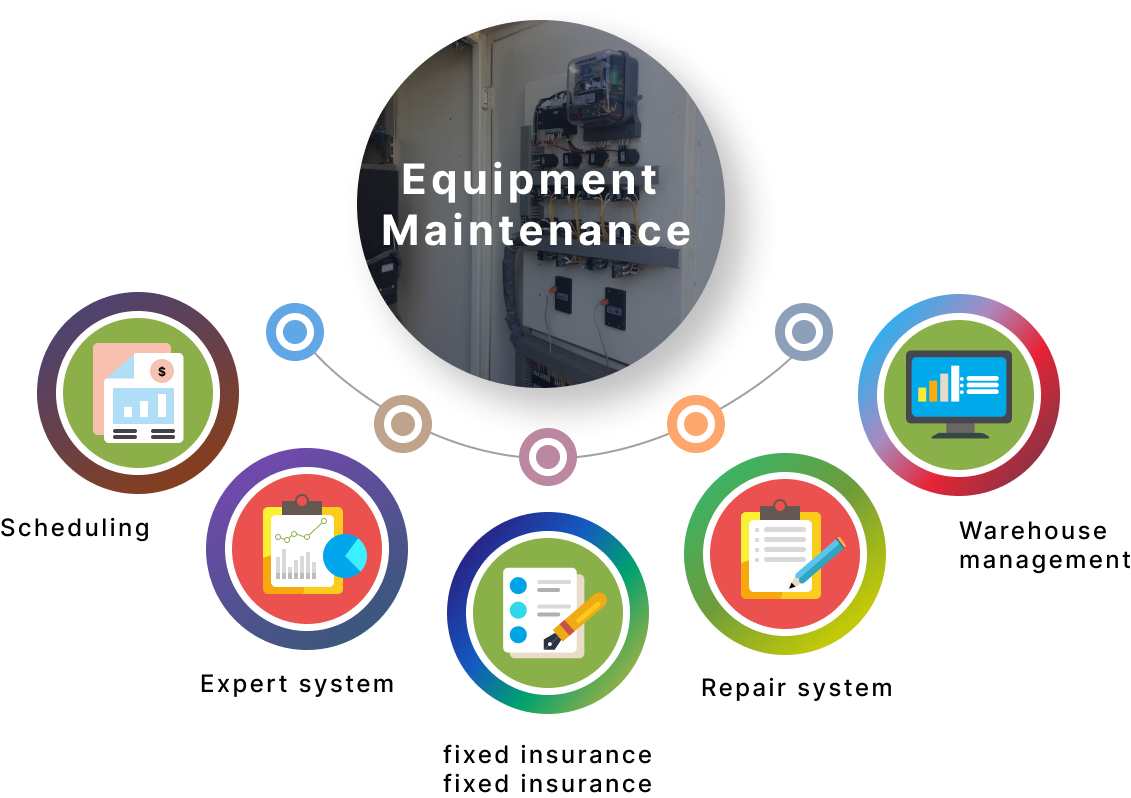

System Overview

Front-End Mobile Device Module

- The system supports Windows/Android/iOS mobile devices

- The product adopts several identification methods (NFC/QRcode/GPS)

- Login operation Authentication

- Equipment maintenance record operations

- Front-End historical data inquiry

- Equipment work search

- Expert database

- Maintenance work

- On-Site service order

- Data transfer operations

Back-End equipment maintenance management module

- Traditional chinese version

- Account authorization management

- Work environment management

- Maintenance time slot management

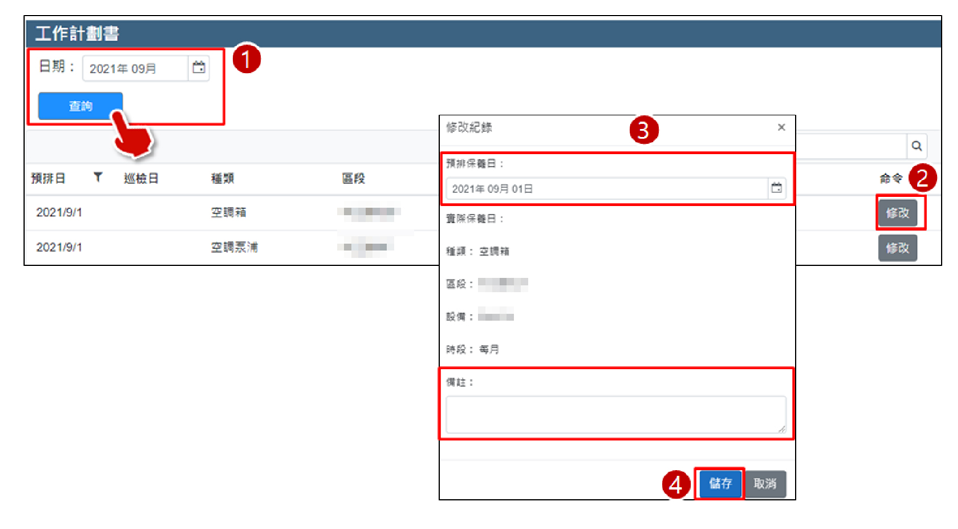

- Scheduling plans

- Maintenance management

- Record audit operations

- Deficiency improvement operations

- Abnormal notifications

- Web input mode

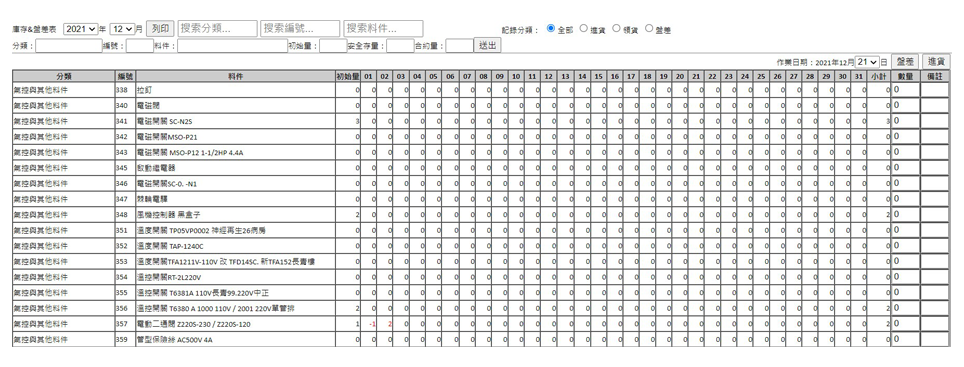

- Warehouse management

Report module

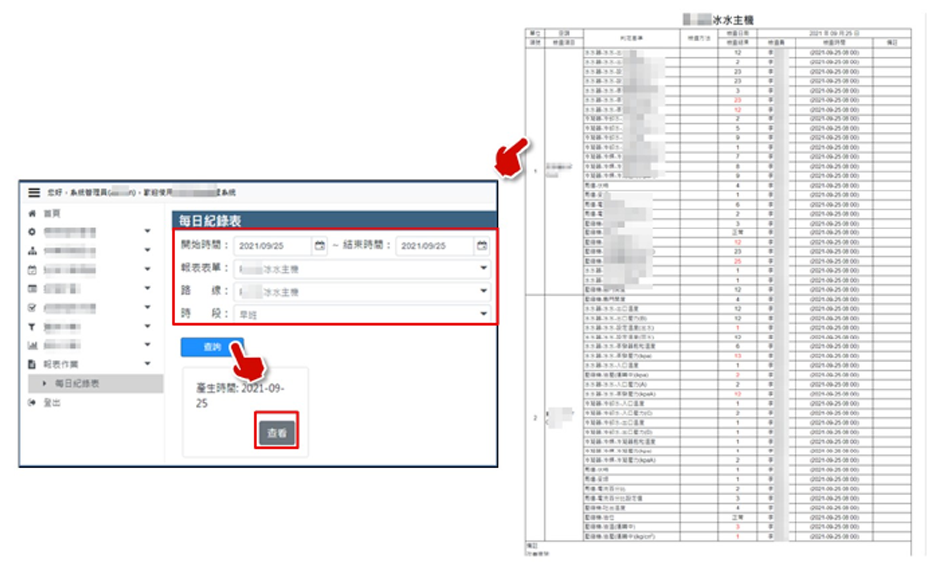

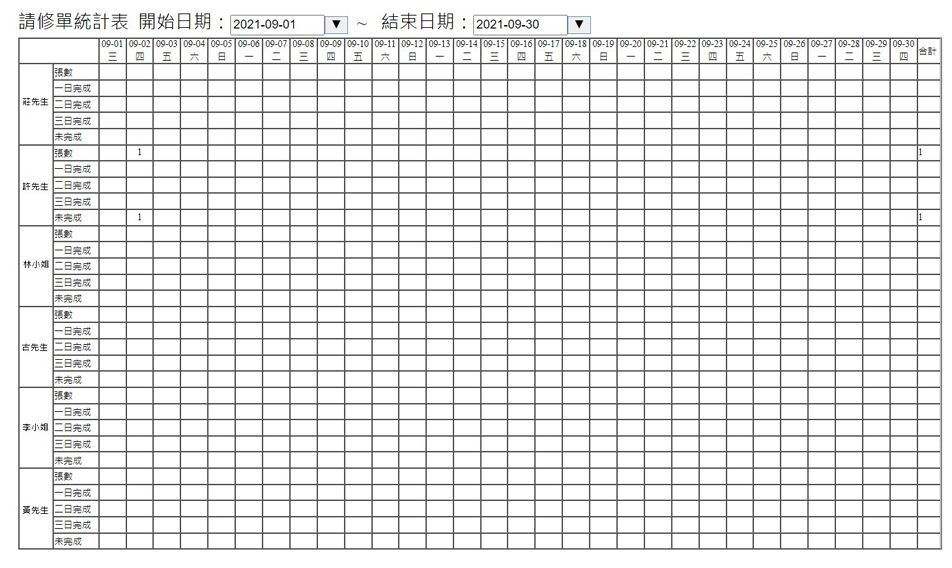

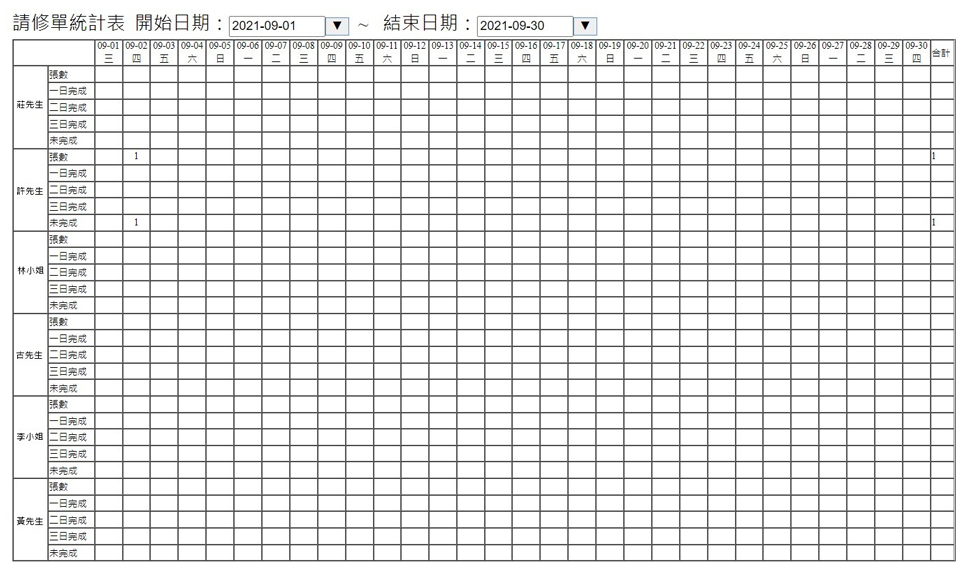

- Daily maintenance records

- Monthly maintenance records

- Deficiency improvement reports

- Monthly work log

- Inventory records

- Comprehensive report generation

- Report template design

(Same report template for similar equipment) - One-click cost estimation maintenance report

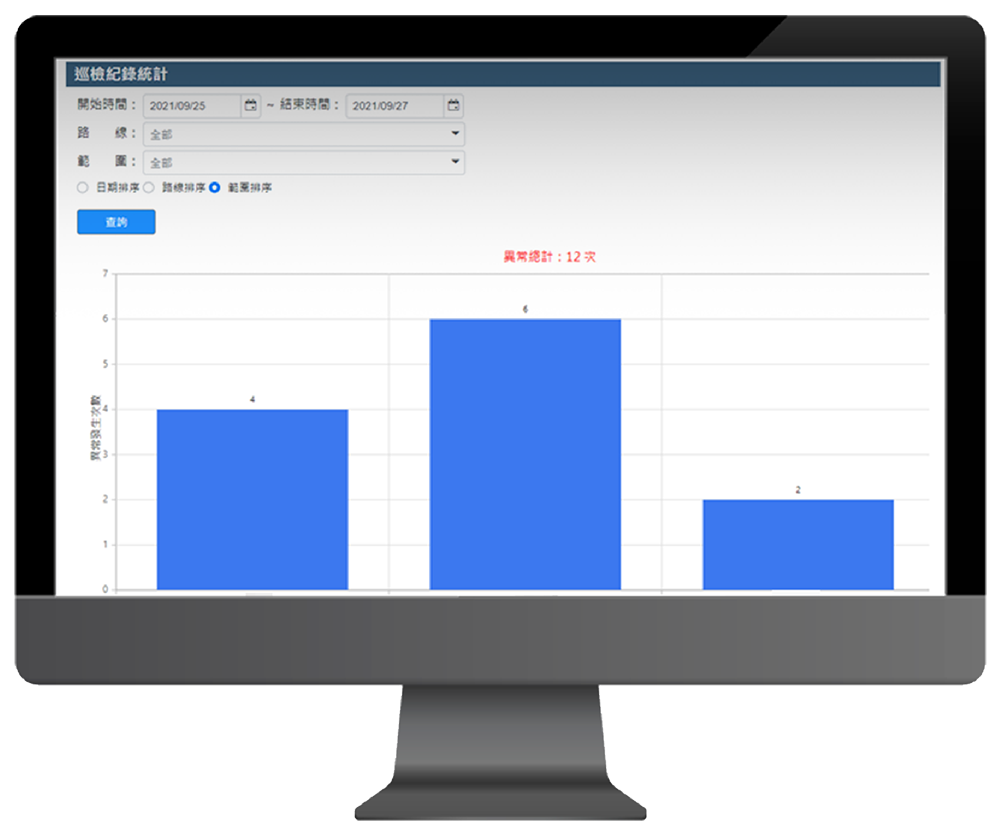

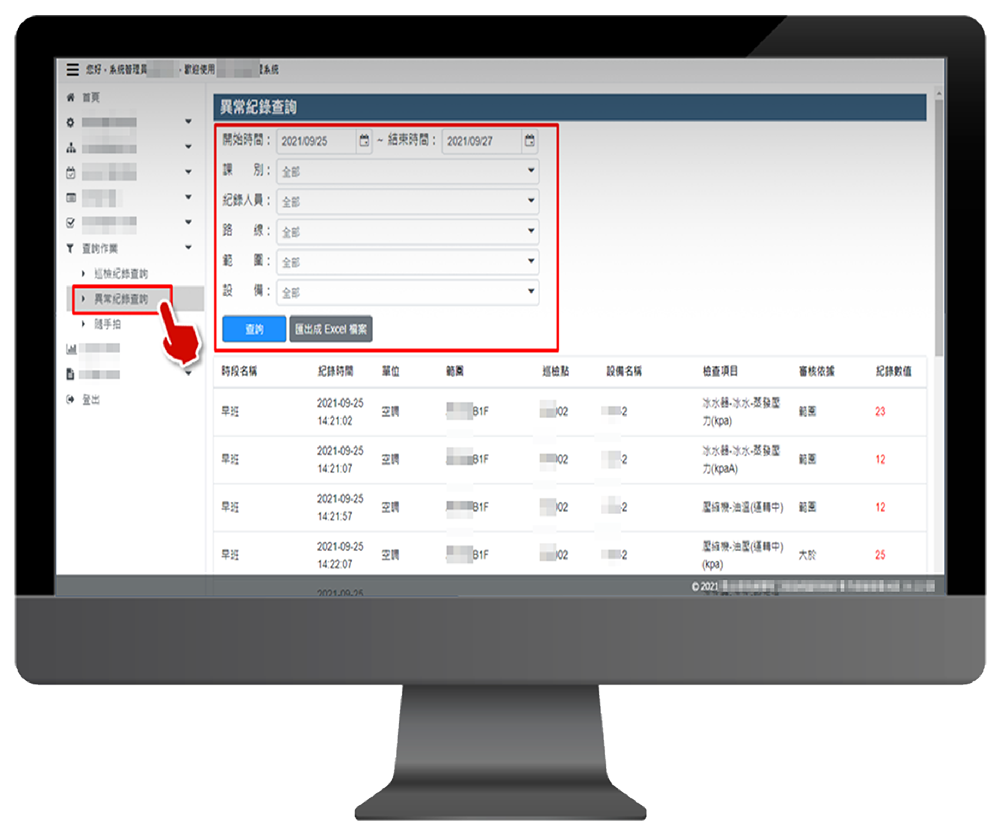

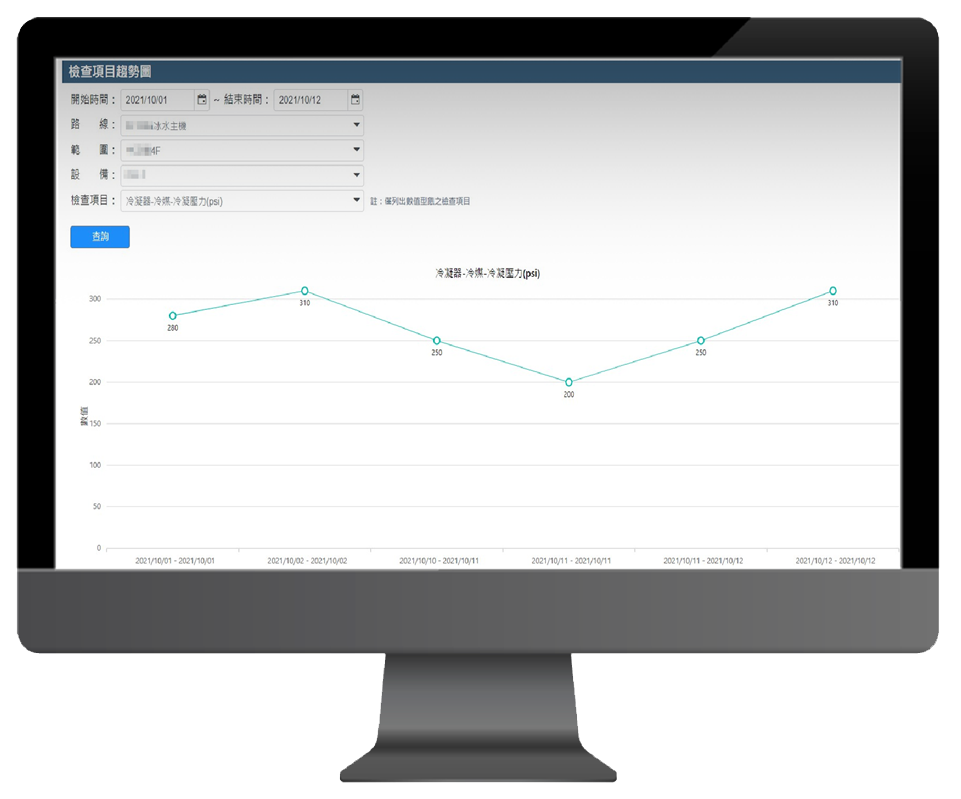

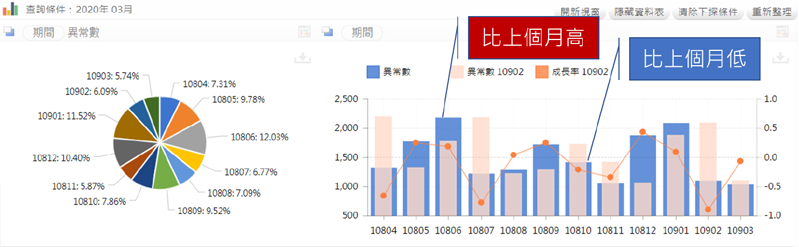

Query and statistics module

- Regular inspection record inquiry

- Exception record query

- Temporary status query

- Statistical Operations

- Digital dashboard

- Overdue request for maintenance queries

- Overdue maintenance queries

- Consumables management tracking

- Key performance indicators dashboard

Management dashboard

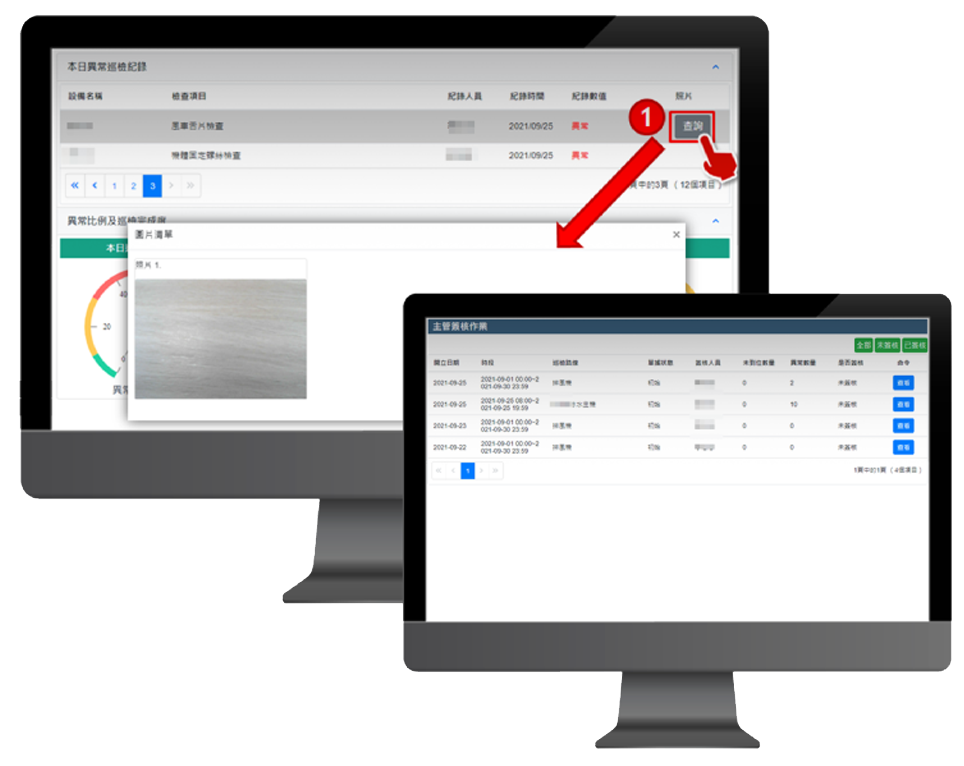

- Today's abnormal scheduled inspection records

- Today's scheduled inspection completion percentage

- Daily/Weekly/Monthly scheduled inspection completion rate

- Key performance indicators dashboard

- Operations dashboard

- Calendar

- Automatic update time settings

System management module

- Provide system parameter setting permissions

- Integration of consumables management, warehouse management, and scheduling management

- No limit on number of accounts or maintenance jobs

- Passes information security App inspection

- Provide digital dashboard

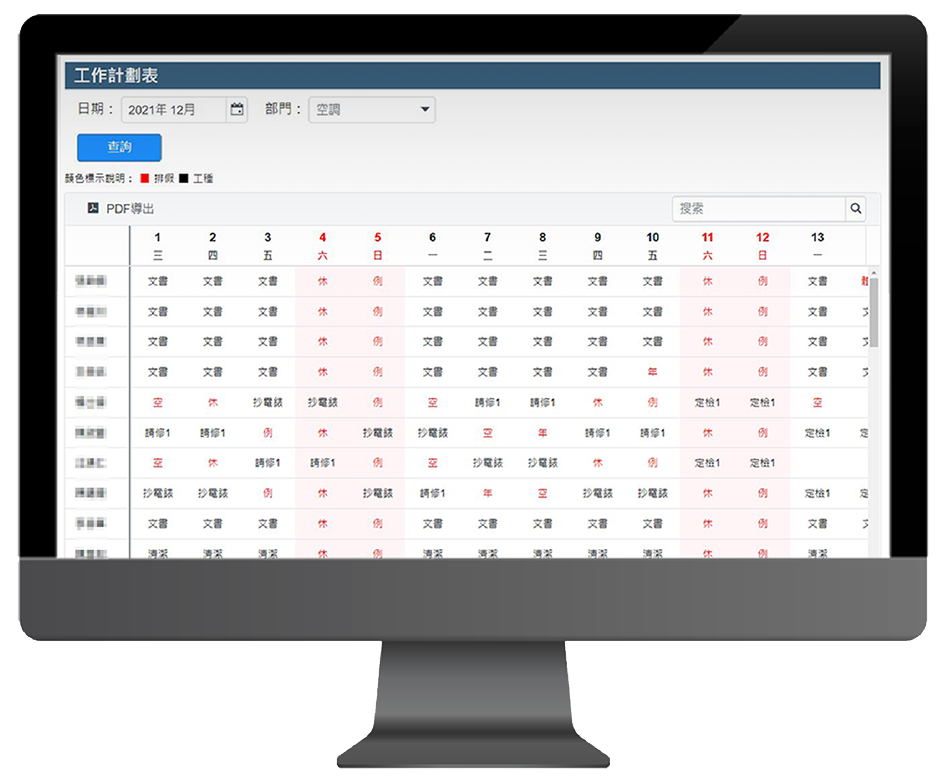

Automatically generate human work shift schedules for Daily/Monthly/Yearly.

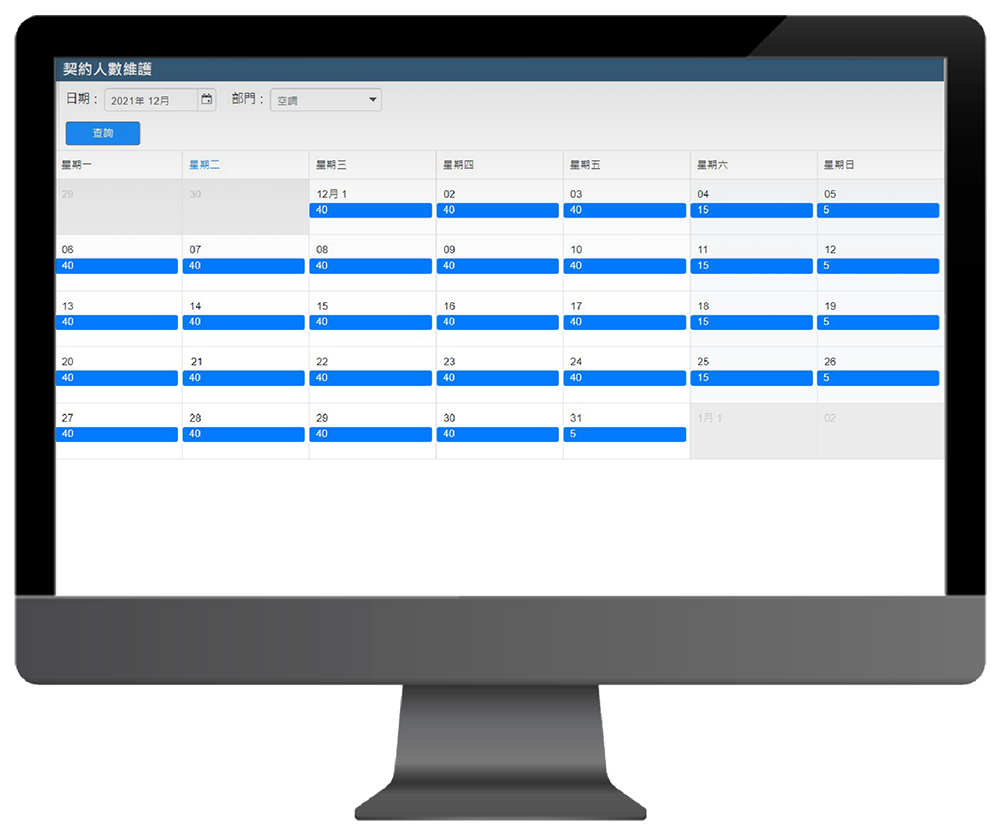

Capable of managing scheduling for personnel, maintenance cycles, inspection schedules, job type maintenance, shift maintenance, leave maintenance, contract staffing levels, and more.

Visualizing equipment management.

Addressing knowledge transfer issues and integrating operation manuals and educational training.

Implementing AIoT and Industry 4.0.

Cost efficiency and material control implementation.

Data database integration, Anomaly Analysis, and More.

Product Description

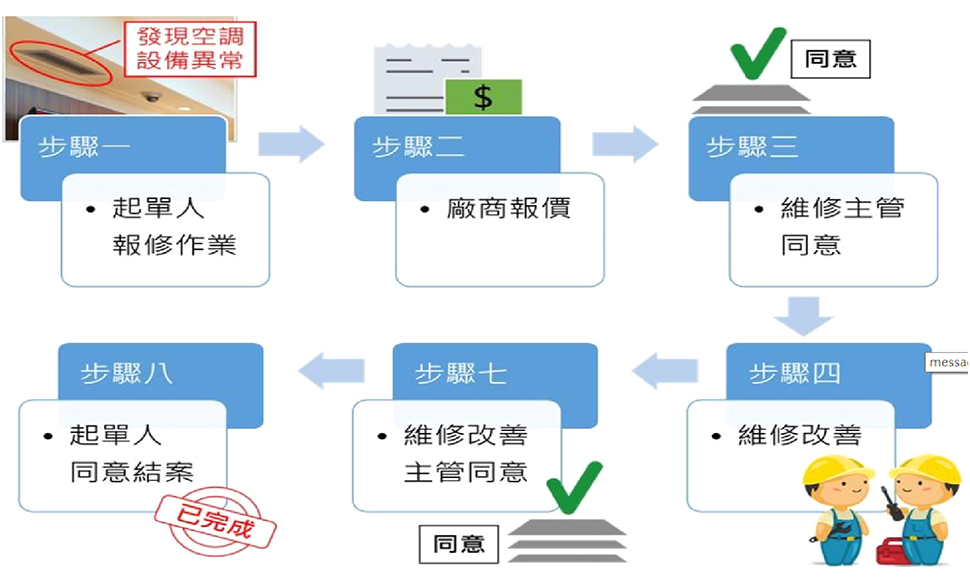

- In response to the movement toward paperless work environment, the work order for routine maintenance operation can be requested through our system in connection with the designed software or application on the front-end devices, such as smart phones or tablets. (customizable).User can quickly view the progress of work order request on the system.

Application Level

Scheduled Maintenance Scheduling, Ad-hoc Repair Assignments, Sensing of Completion, Progress Reporting, Work Assignment Management, Maintenance History, and Warranty Inquiry.

Comprehensive Systematic Equipment Management, including Equipment Model, Equipment Name, Customer Name, Installation Location, Warranty Period, Safety Stock, and more.

We provide a comprehensive knowledge base for all types of equipment faults, allowing maintenance personnel to quickly understand equipment issues. Through mobile devices, they can search for relevant solutions, which aids in knowledge transfer and educational training.

Equipment Maintenance schedule planning

Log into the Equipment System with a Portable Mobile Device.

Equipment maintenance / Equipment conservation / Patrol inspection work / Manitenance workElectronic patrol and inspection repair system

Show daily work and equipment positioning points.

Patrol and inspection records / Maintenance work / Equipment work / Maintenance applicationIntrgration of the patrol and map information systems

Connection of a map information system to search for the equipment position.

Each building / Each floor / Each area / Space numberExpert database system

Connection of an expert system to indicate SOP manipulation.

Operation SOPs / Equipment data / Operation manual / Photo/videoCombination of equipment inspection and equipment conservation

Combination of inspection equipment to input the result.

Data Monitoring / Abnormal alerts/Push notifications / AIoT Integration / Location PlanningSafety Storage

Asset consumables and parts inventory.

Precise Inventory Control / Cost Savings / Material Shelf Integration / Contractor Management and ControlBI ward dashboard display

Creation of a patrol and inspection result database

Abnormal data / Abnormal notifications / Handover items / Down analysis